Our warming mats

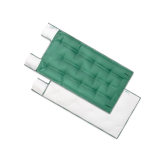

The textile products of the MoeckWarmingSystem® are composed of up to 3 carefully selected technical textiles, each of which fulfills specific functions and, in combination, forms an optimally coordinated system. For example, the green side facing the patient consists of a fine-pored filament fabric. The resulting air permeability of the polyester fabric enveloping the patient leads to a uniform air flow, thus achieving ideal patient temperature control. In addition, the carbon fibers embedded in the fabric counteract static charging.

The white side facing away from the patient is also made of polyester, but is equipped with a polyurethane coating that serves as an air and fluid barrier. In this way, the applied heat is conducted directly to the patient. In addition, the thermal underlays between the green and white sides contain a filling consisting of one or more layers of 3-dimensional (3d) spacer fabric. Due to its elasticity, this intermediate layer ideally adapts to the body shape and weight of the patient lying on it, thus providing balanced pressure relief and improved lying comfort. On the other hand, due to its 3-dimensional structure and its coarse-pored structure, the spacer fabric has a highly efficient moisture-conducting function, which helps to remove moisture downwards from the patient.

All textile materials used in Moeck & Moeck warming underpads are characterized by high strength, durability and radiolucency. They are completely latex-free and can be reprocessed.